Provide you with the latest enterprise and industry news.

Aeration plays a critical role in maintaining healthy aquatic environments, especially in aquaculture and wastewater treatment. Among the various aeration technologies available, Paddle Wheel Aerator Water Cooling systems have gained popularity for their unique design and functionality. However, understanding their advantages and limitations compared to other aeration devices is essential for making informed choices. This article explores how Paddle Wheel Aerator Water Cooling stacks up against alternative aeration methods.

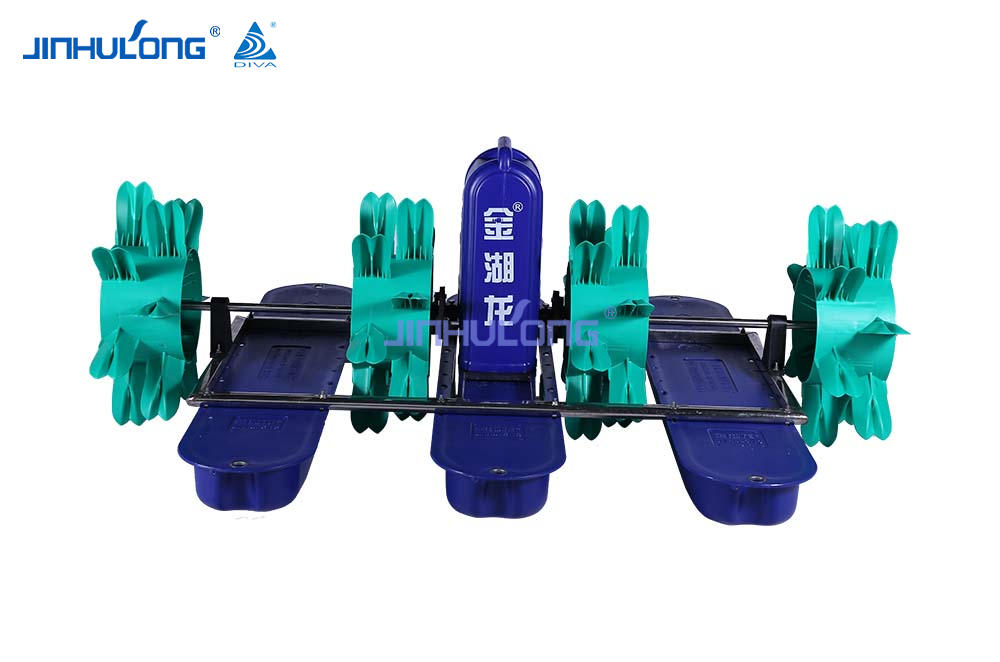

Efficient Oxygen Transfer and Water Circulation

One of the primary advantages of Paddle Wheel Aerator Water Cooling is its ability to provide both effective oxygenation and water circulation simultaneously. Unlike diffused aerators that mainly focus on oxygen transfer through fine bubbles, paddle wheel systems physically agitate the water surface, increasing oxygen absorption and promoting uniform water movement. This dual function enhances dissolved oxygen levels throughout the water body and prevents stratification, which is critical for aquaculture ponds.

Energy Consumption and Operational Costs

Compared to some aeration devices like surface fountains or high-pressure diffusers, Paddle Wheel Aerator Water Cooling systems tend to have moderate energy consumption. They use mechanical paddle wheels powered by electric motors, which can be optimized for different operational speeds. While not low in energy use, their efficiency in mixing and aeration often offsets energy costs by improving aquatic health and productivity. However, more energy-efficient options like low-speed surface aerators might outperform them in energy savings under certain conditions.

Durability and Maintenance Requirements

Paddle Wheel Aerator Water Cooling units are generally robust, designed to withstand harsh aquatic environments. Their mechanical components are accessible for maintenance, and many are built with corrosion-resistant materials. However, compared to diffused aeration systems, which have fewer moving parts submerged in water, paddle wheel aerators may require more frequent maintenance due to mechanical wear and potential debris interference. Proper upkeep is necessary to maintain their operational efficiency.

Water Depth and Application Versatility

One limitation of Paddle Wheel Aerator Water Cooling is its suitable performance range concerning water depth. They are effective in shallow to medium-depth water bodies where surface agitation can influence the entire water column. In contrast, diffused aerators can deliver oxygen at various depths, including deeper waters, making them suitable for reservoirs or deeper ponds. Therefore, the choice depends on the specific aquatic environment and desired aeration depth.

Noise Levels and Environmental Impact

Paddle Wheel Aerators produce moderate noise levels during operation due to the mechanical movement of paddles. In contrast, some submerged aerators or diffusers operate more quietly, which may be preferable in residential or noise-sensitive areas. Additionally, the surface agitation caused by paddle wheels can sometimes disturb sediment or aquatic organisms more than gentle diffused aeration methods.

Cost and Installation Complexity

Initial investment and installation for Paddle Wheel Aerator Water Cooling systems are typically straightforward, especially for small to medium-sized ponds. They do not require complex underwater piping or air compressors like some diffused aeration setups. This simplicity can reduce upfront costs and installation time. However, for very large or deep water bodies, alternative aeration systems may be more cost-effective in the long term.

Conclusion: Choosing the Right Aeration Based on Needs

Paddle Wheel Aerator Water Cooling offers significant advantages in oxygen transfer efficiency, water circulation, and ease of installation, making it a strong choice for many aquaculture and water management applications. Nonetheless, considerations such as energy consumption, maintenance needs, water depth suitability, and noise should guide the selection process. Understanding these pros and cons helps stakeholders select a suitable aeration device tailored to their specific environmental and operational requirements.

中文简体

中文简体 English

English Español

Español

0086-576-84893666

0086-576-84893666  0086-15757686666

0086-15757686666

Tangshan Chen, Shabu Town, Huangyan, Taizhou, Zhejiang

Tangshan Chen, Shabu Town, Huangyan, Taizhou, Zhejiang